Getting Started with Seam Bonding Non-Woven Polyester

Seam bonding, a critical technique for assembling non-woven polyester fabrics, involves creating strong, durable joints without traditional sewing. This method is pivotal for products where traditional stitching may fail or where waterproofing is necessary. One common challenge is achieving consistent bond quality across different thicknesses and textures of non-woven polyester, which can be overcome by selecting the appropriate bonding method tailored to the specific material characteristics.

Industries ranging from automotive to healthcare rely on non-woven polyester for its flexibility and strength, making effective seam bonding crucial for product integrity and performance.

What Makes Non-Woven Polyester Special?

Non-woven polyester differs significantly from woven polyester, primarily due to its structure. It is manufactured through processes that bond fibers together mechanically, thermally, or chemically rather than weaving them on a loom. This gives non-woven polyester unique properties such as uniformity, breathability, and high tensile strength, making it ideal for applications like filtration systems, disposable clothing, and upholstery.

The Importance of Strong Seam Bonds

For products like filters and geo textiles, the strength of seam bonds is non-negotiable. Weak or inconsistent bonds can lead to product failure under stress or when exposed to environmental factors. Common issues include seam fraying or bond break down over time, which can be mitigated by understanding the bonding process and the materials' responses to different bonding techniques.

Techniques for Bonding Non-Woven Polyester Seams

Exploring various seam bonding methods allows manufacturers to choose the most suitable technique for their specific application needs. Each method has its own set of advantages and challenges, making it vital to understand the nuances of each.

Heat Welding Techniques

Heat welding utilizes controlled heat to melt polyester fibers slightly, creating a seamless bond as it cools and solidifies. This method is straightforward and efficient but requires precise temperature control to avoid damaging the fabric. Heat welding is particularly effective for large-scale projects requiring strong, uniform seams.

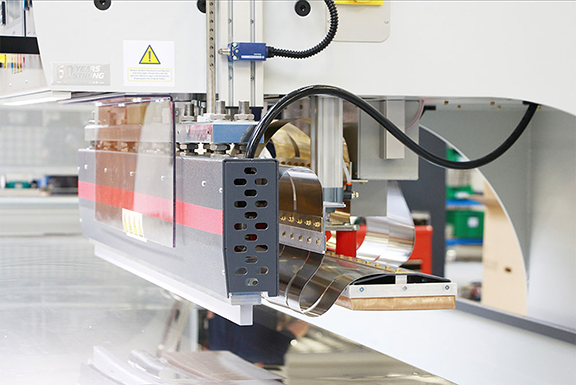

Ultrasonic Welding for Precise Bonds

Ultrasonic welding offers precision by using high-frequency vibrations to generate heat between fabric layers, bonding them without the need for external heat sources. This technique is excellent for delicate applications where precise control over the bonding process is necessary. However, it requires specialized equipment and some trial and error to perfect the settings.

Adhesive Bonding Solutions

In scenarios where thermal or ultrasonic welding is impractical, adhesive bonding provides a viable alternative. This method involves applying a glue or adhesive specifically designed for non-woven polyester, which can offer flexibility and durability. The choice of adhesive and the application method are critical for ensuring a strong, lasting bond.

Factors That Impact Seam Bonding Success

Several factors influence the success of a seam bonding process, from the material characteristics to the environmental conditions of the manufacturing space.

Material Characteristics Matter

The thickness and density of non-woven polyester can greatly affect how well it bonds. Thicker or denser materials may require more heat or a longer bonding time, making it crucial to adjust methods accordingly.

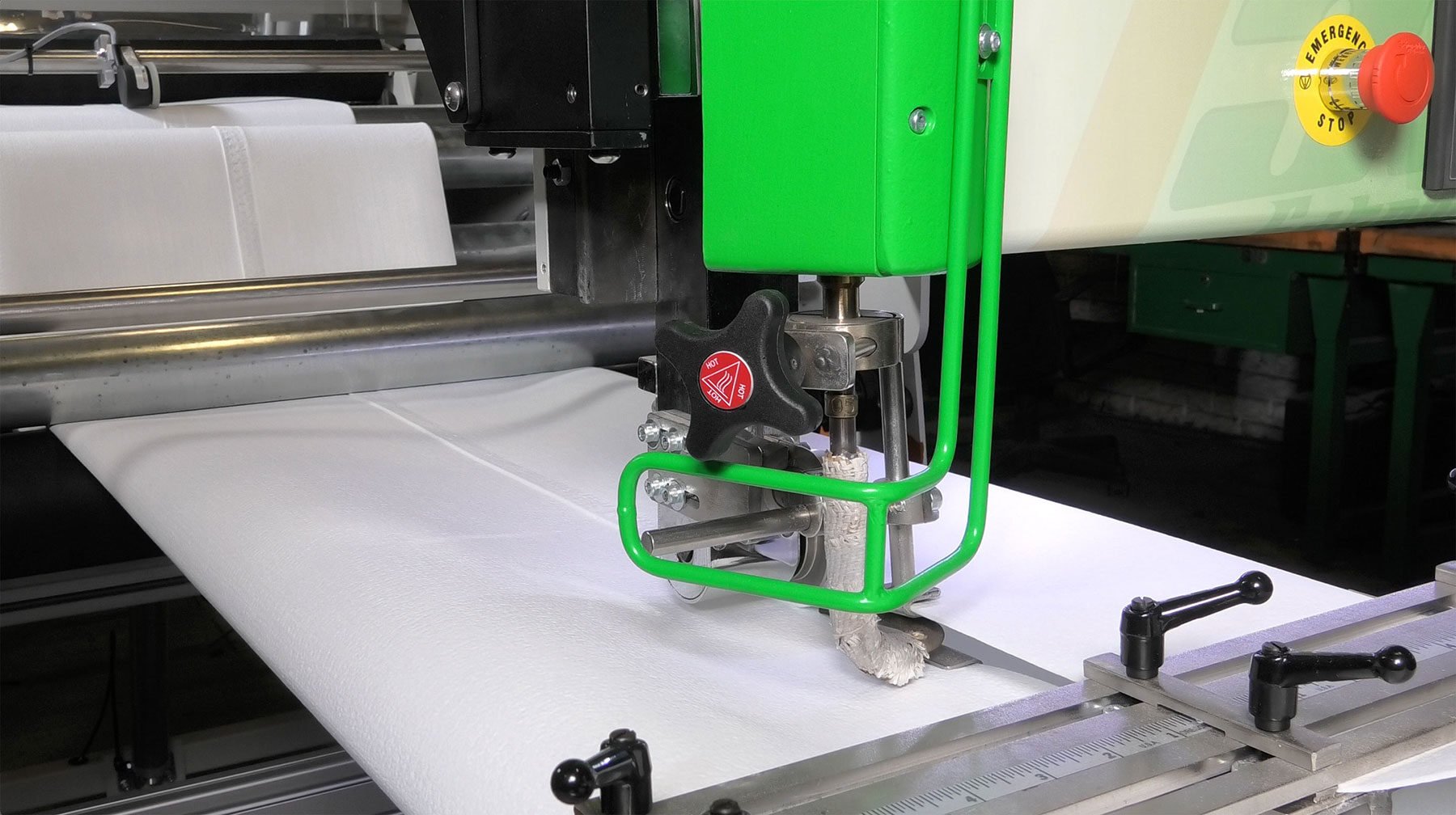

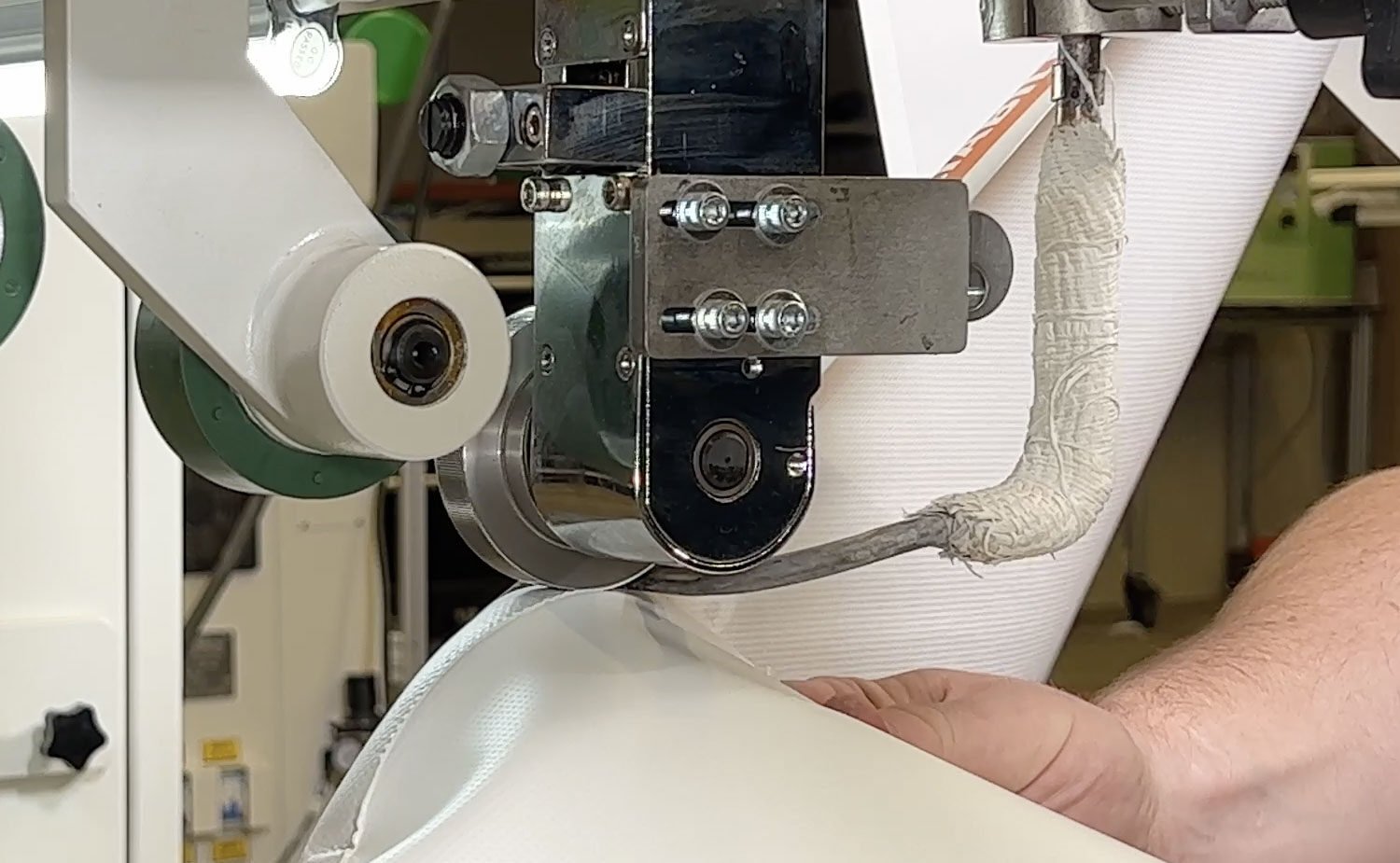

Equipment Selection and Setup

Selecting the right equipment and configuring it correctly is foundational to achieving good bonding results. Equipment malfunctions or improper settings can lead to poor quality bonds, so regular maintenance and calibration are key. Learn more about Miller Weldmaster's solutions here.

The Role of Environmental Conditions

Temperature and humidity play significant roles in how well non-woven polyester bonds. High humidity can prevent proper bonding, while too much heat can warp or melt the fabric. Preparing the workspace to control these factors is essential for consistent quality.

Tips for Achieving Strong Seam Bonds

Creating durable and strong seam bonds is achievable by following best practices and focusing on preparation and quality control.

Preparation is Key

Properly preparing the materials before bonding includes cleaning and drying the fabrics, aligning them accurately, and securing them in place to prevent movement during the bonding process.

Bonding Best Practices

Keeping pressure and timing consistent during the bonding process ensures uniformity across the production batch. Adjustments may be necessary depending on the project specifics, but close monitoring can prevent many common bonding issues.

Post-Bonding Quality Control

After bonding, testing the seam strength is crucial to ensure the product meets the required specifications. Techniques like stress testing or visual inspections can help identify potential issues before the product goes to market.

How Miller Weldmaster Can Help

Miller Weldmaster specializes in equipment and solutions tailored for effective seam bonding of non-woven polyester. Our range of machines and our expertise in thermal and ultrasonic bonding techniques make us an ideal partner for your manufacturing needs.

Equipment Designed for Seam Bonding

Our equipment is specifically designed to handle the nuances of non-woven polyester, ensuring efficient and reliable seam bonding. Features like adjustable heat settings, precise pressure controls, and user-friendly interfaces make our machines stand out in the market.

Customized Solutions for Unique Needs

Understanding that each project has unique requirements, Miller Weldmaster prides itself on working closely with clients to develop customized solutions that address specific challenges. Whether you need a machine with special capabilities or advice on the best bonding technique for your material, we are here to help.

Why Miller Weldmaster Is the Perfect Partner

Choosing Miller Weldmaster means more than just buying a machine; it means forming a partnership that will help your business succeed. Our commitment to quality, innovation, and customer support ensures that you receive not only the best equipment but also comprehensive service that covers training, maintenance, and troubleshooting.

Quality and Reliability That Stand Out

Our machines are built to last, designed with the highest quality standards and for ease of use, ensuring they withstand the demands of industrial environments.

Comprehensive Customer Support

We offer extensive training and support services, ensuring you get the most out of your equipment and that your staff are well-prepared to use it effectively.

Building Long-Term Relationships

Our focus on long-term relationships means we continually work to meet your evolving needs with new technologies and customized solutions, ensuring you always have a partner in your corner as your business grows.

For more information on our non-woven polyester seam bonding solutions, visit our detailed material guide here.